Bulk Process Equipment, Bulk Solid Material Processing & Handling Equipment, Industrial Bulk Solids Material Handling Systems

|

Material Handling & Processing Equipment |

About Us | Material Handling Equipment | Solid Material Processing | Plant Services | Manufacturers | Equipment Photos | Clients | Case Studies | News | Contact Us | Home

THERMO RAMSEY: Standard Modular, Volumetric Feeders

Volumetric feeders are utilized in bulk material feeding applications when the feed rate and total weight measurements are not necessary and accuracy requirements of ±1-2 % are permissible.

Volumetric feeders are utilized in bulk material feeding applications when the feed rate and total weight measurements are not necessary and accuracy requirements of ±1-2 % are permissible. Volumetric adjustments are accomplished through the use of an open loop variable speed control, which can be operated either locally or remotely. Thermo Ramsey works closely with customers to ensure that each system meets their expectations for performance and reliability, whether the application is handling pellets, flakes, powders or fibers.

Volumetric feeders are utilized in bulk material feeding applications when the feed rate and total weight measurements are not necessary and accuracy requirements of ±1-2 % are permissible. Volumetric adjustments are accomplished through the use of an open loop variable speed control, which can be operated either locally or remotely. Thermo Ramsey works closely with customers to ensure that each system meets their expectations for performance and reliability, whether the application is handling pellets, flakes, powders or fibers.

Benefits:

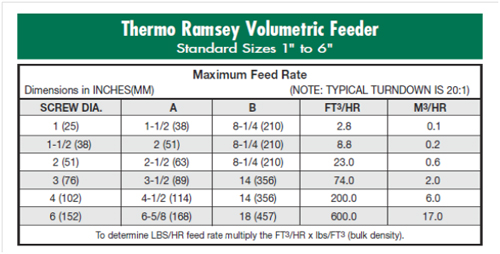

Thermo Ramsey's standard modular volumetric feeder is available in six sizes and provides accurate feeding up to 600 ft3 per hour. The unit's design affords the ability of handling a broad range of bulk solid materials with various characteristics and may be equipped with an integral, free-flowing hopper, as shown, or an optional dust containment trough cover for use directly beneath a bulk material storage bin. The modular design of the volumetric feeder permits selection of the most economical design required for a specific application with the unparalleled ability to upgrade the design as materials and characteristics change. Various customer options may be added to allow the unit to adapt to abroad range of feeding applications and materials:

- A standard feeder with static hopper, trough and feed screw for free-flowing materials.

- An agitator conditioner feeder with a secondary trough conditioning screw for semi-flowing materials.

- A vibrated feeder using controlled vibration for non-free-flowing materials.

Specifications & Dimensions:

Sizes (inches): 1, 1-1/2, 2, 3, 4 and 6

Materials of Construction: Contact surfaces available in carbon steel, 304 stainless steel and 316 stainless steel. Non-contact surfaces: carbon steel, painted exterior surfaces.

Drive: Sizes 1, 1-1/2 and 2 inches - DC-SCR controlled, 1/2 hp, TENV motor enclosure, supply 120v, 1 phase, 60 Hz, NEMA-12 controls enclosure.

Sizes 3 and 4 inches - DC-SCR controlled, 3/4 hp, TENV motor enclosure, supply 230v, 1 phase, 60 Hz, NEMA-12 controls enclosure.

Size 6 inches - DC-SCR controlled, 1 hp, TENV motor enclosure, supply 230v, 1 phase, 60 Hz, NEMA-12 controls enclosure.

Feed Tube and Screw: Straight, horizontal/end discharge - downspout, vertical discharge with or without end bearing, optional. Wire screw or flighted screw.

Supply Hopper: Hoppers available as an extension of the feed trough,1-1 1⁄2 ft3 through 15 ft3.